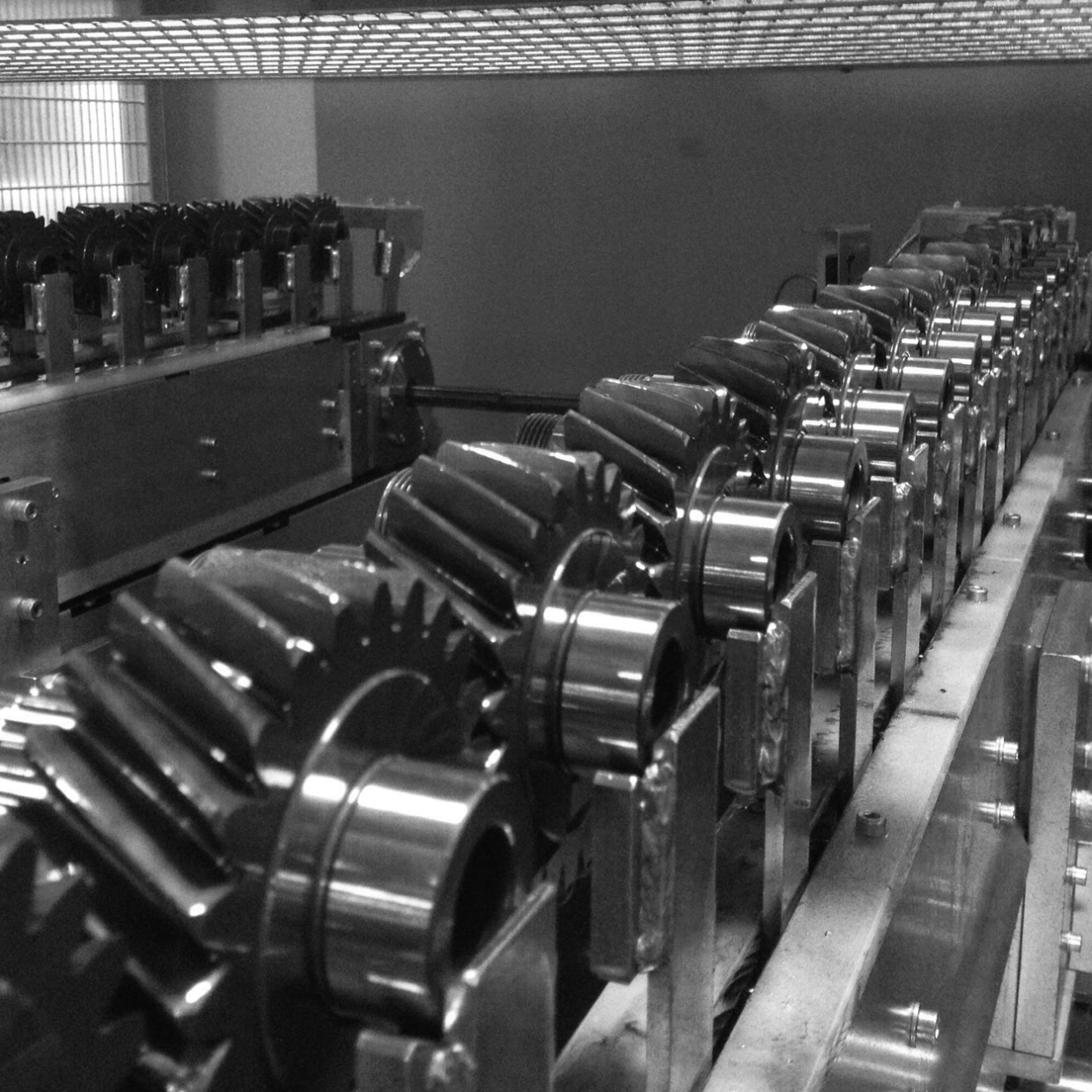

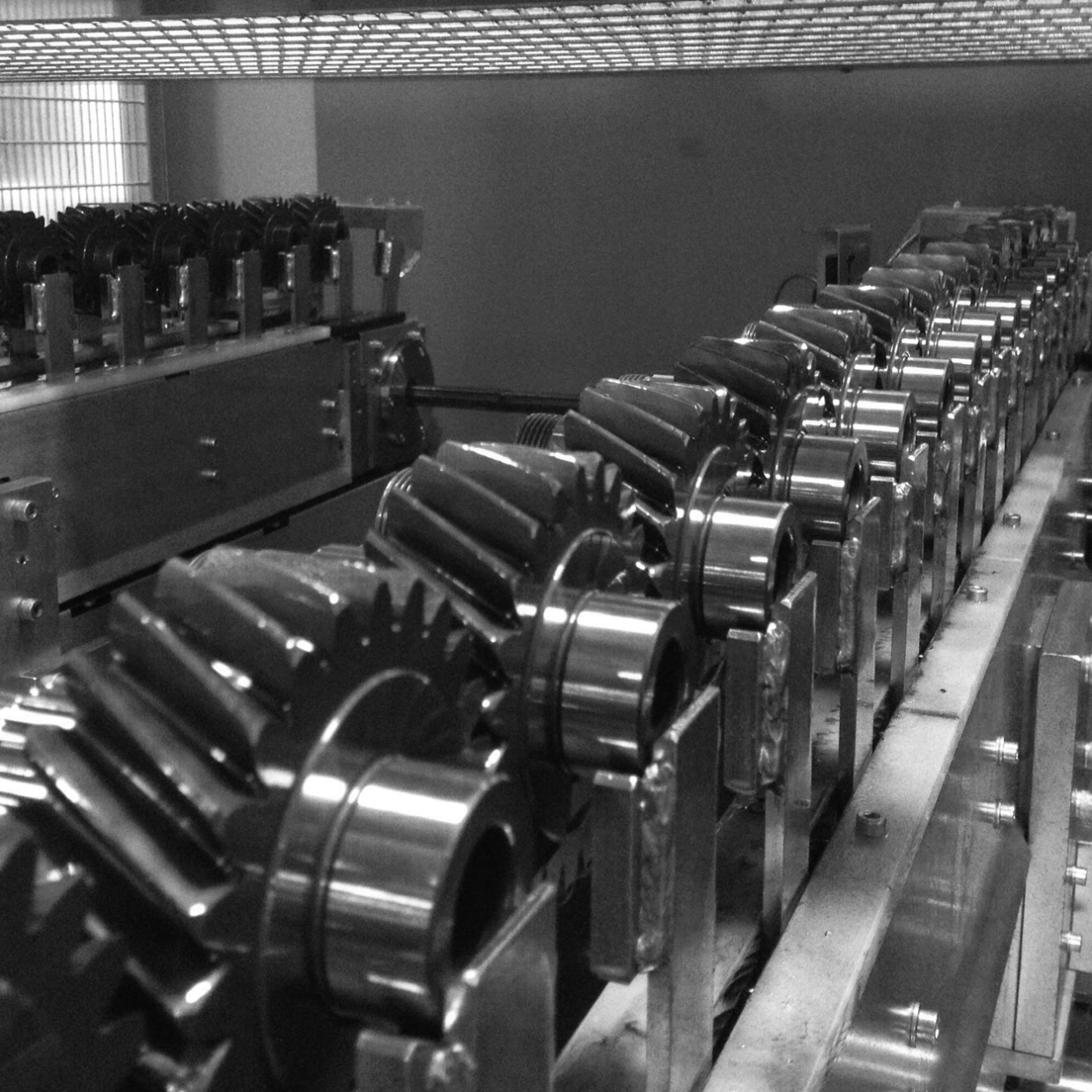

Whether it’s for aerospace or automotive, transportation or pumps, power generation, or robotics, precision is a must for effective gear manufacturing. Riley Gear Corporation, based in St. Augustine, Florida, can execute to the highest gear precision standards set by the American Gear Manufacturers Association. Our facilities are capable of producing gears .25 to 40 inches in pitch diameter to AGMA Class Q15 or DIN 2 specifications via a full complement of state-of-the-art custom gear manufacturing assets, including Reishauer, KAPP, and Samputensili. Our strict quality control procedures ensure that all of our work adheres to the highest standards.

Riley Gear’s manufacturing capabilities include the machining of gear blanks, hobbing, shaping and broaching of internal and external gears, precision grinding of internal and external gear teeth, as well as the grinding of inside and outside diameters and gear faces.

Whether it’s for aerospace or automotive, transportation or pumps, power generation, or robotics, precision is a must for effective gear manufacturing. Riley Gear Corporation, based in St. Augustine, Florida, can execute to the highest gear precision standards set by the American Gear Manufacturers Association. Our facilities are capable of producing gears .25 to 40 inches in pitch diameter to AGMA Class Q15 or DIN 2 specifications via a full complement of state-of-the-art custom gear manufacturing assets, including Reishauer, KAPP, and Samputensili. Our strict quality control procedures ensure that all of our work adheres to the highest standards.

Riley Gear’s manufacturing capabilities include the machining of gear blanks, hobbing, shaping and broaching of internal and external gears, precision grinding of internal and external gear teeth, as well as the grinding of inside and outside diameters and gear faces.

Riley Gear Corporation invests in state-of-the-art industrial gear manufacturing and inspection technology to deliver your gear designs and concepts seamlessly and cost-effectively through final production. The latest in cutting and grinding technology combined with state-of-the-art robotic automation ensures quality, accuracy, and on-time delivery. When you choose Riley Gear Corporation as a development partner, many production resources from some of the top names in gear grinding equipment are working for you. Some of our assets include:

Check out the list of gear manufacturing equipment available at our facilities in Florida and New York. You can also view and compare the capabilities and dimensions of our precision gears.

View Equipment ListOur company’s driving force is to consistently provide quality across all products that we manufacture. Our manufacturing process is designed to meet your required specifications. With our top-of-the-line gear quality control, we guarantee that we’ll provide the best end product for your application.

Riley Gear Corp ensures that gears produced will meet your requirements. Our professionals utilize specialized equipment, including:

Our company’s driving force is to consistently provide quality across all products that we manufacture. Our manufacturing process is designed to meet your required specifications. With our top-of-the-line gear quality control, we guarantee that we’ll provide the best end product for your application.

Riley Gear Corp ensures that gears produced will meet your requirements. Our professionals utilize specialized equipment, including:

The experts at Riley Gear are here to provide you with quality gears and components for your next job. With over 75 years of engineering and manufacturing experience, we can help turn your concepts into efficient solutions. We inspect customer designs and produce custom gear equipment for a variety of industries, ranging from precision gears and gearboxes to power transmission assemblies.

If you’re ready to take the next step, please give us a call or fill out the form below to request a quote. Our representatives will provide you with the answers and assistance you need to get started on your next project.

Call Us TodayWe look forward to receiving your RFQ. Our Sales team will be in touch with you shortly.